ABB motors

As ABB's Value Provider (VP) for motors in Scotland we offer a wide range of aluminium & cast iron motors, supporting a wealth of applications, and built to a huge variety of exacting specifications.

Find your local ABB motor Value Provider in the UK

See the benefits of inverters controlling motors in the food and beverage industry.

ABB's SynRM motor range: the perfect partnership of drive and motor.

ABB WIMES motors - Versatile, affordable, low voltage motors created for the water industry - but which are equally at home in a range of other sectors. They fully comply with (and in fact, exceed) the Water Industry Mechanical & Electrical Specification. Designed and built to withstand the rigours of life in water & wastewater applications, these motors are ideally adapted to their challenging environment with C3M corrosion tolerance, labyrinth & V-ring seals and stainless-steel nameplates. See more information on WIMES compliant motors.

ABB Process Performance Motors - Built for demanding industries such as: metals, pulp & paper and minerals & mining, these ABB motors are often used in continuous process industries, project OEMs or EPCs. These motors set the standard for their ability to perform reliably, and continuously under the most challenging circumstances including heavy duty applications. With the lowest possible environmental impact and life cycle costs, these ABB motors come with a 3 year warranty as standard.

ABB General Performance Motors - Designed for use with pumps, fans and compressors, these robust ABB motors are often used in industry & tailored serial / project OEMs. With the ability to be changed to your exact specifications via a wide range of add-on variants, these motors come free from all unnecessary elements - meaning you only pay for the enhancements you require.

ABB Hazardous Area Motors - Specifically made for atmospheres containing explosive gas or dust in the atmosphere, these specialised ABB motors can withstand the pressure of an explosion created inside the enclosures and prevent the explosion from propagating through gaps into the atmosphere.

Motors & why they fail - There are 6 reasons why your motor is likely to fail. Motor age and operating hours have surprisingly little to do with it. What directly impacts on the lifespan of your motor may surprise you.

SynRM motors - full motor control, down to zero speed in a motor drive package unlike any other.

ABB's Motor Optimiser - select the perfect motor, every time.

See ABB's exciting new development in condition monitoring for low voltage motors - motors so intelligent they self-diagnose issues in your operating system before they ever become problems.

See how your motor can advise you of issues before they arise with the ABB Abilioty Smart Sensor.

Problems with bearing currents on low voltage motors? Find out how you can mitigate them with ABB's product notes on bearing current mitigation. And now ABB has introduced the new Smart Sensor for Dodge mounted bearings: your early warning system for problems with vibration and temperature. With the same ease of use as the ABB Smart Sensor for motors, the new smart bearing sensor will identify problems such as insufficient lubrication, which accounts for 80% of bearing failures. Compact, with wireless connectivity, it helps you remotely monitor your critical components, detecting a fault before it becomes a failure.

2019 - a motor odyssey!

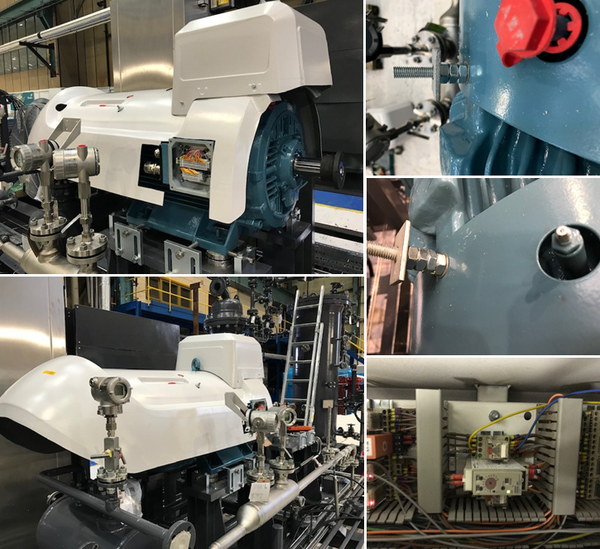

Below is an example of the skilled workmanship of EDC engineers with an ABB motor. Requiring a heat canopy prior to being shipped to Dubai, our engineers had to allow for grease points and motor, thermistor and bearing termination boxes - all of which involved precise cutting and measurements for holes with the cover. And the futuristic looking design, which made the motor look a little like a NASA shuttle, fitted like a glove!