CASE STUDY 6 - RETROFIT OF ABB VSDS MAKES HUGE SAVING FOR INSURANCE COMPANY

Take a chill bill! Can using variable speed drives save you 176,280 kW hours per annum—and with a payback time of only 10 months?

Fitting ABB VSDs to chiller pumps on a refrigeration plant at an insurance company office block has made dramatic savings for one of our customers.

The pumps on site were providing cooling water (at between 6-10 degrees C) to Air Handling Units (AHUs) for cooling during the summer.

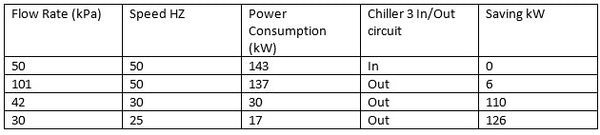

Rated at 160kW, the pumps ran at a fixed speed of 50hZ, consuming 143kW. Working with Trane engineers, EDC retrofitted the drives in the office block which was built circa 1983 – when it was designed for high occupancy, and the heat created by the older generation of computer monitors.

Replacing the chillers for smaller units would be both time consuming and costly for the company. But the addition of inverters – including two 160kW HVAC ACH580-01-0293A-4 drives - to the existing operation enabled the pump speed to be reduced from 50hZ to between 25 –30hZ (based upon returned water temperature). As a consequence the energy consumption duly dropped from 143kW to just 17kW @ 25hZ and 30kW @ 30hZ. Flow measurements were taken at the furthest AHU to confirm the correct operation.

Another benefit was that the condenser cooling demand was reduced, making additional savings. The company now has a correctly climatically controlled office block, run as efficiently and as energy consciously as is possible.

If you are in Scotland or the north east, and have chiller plants on your site, contact EDC to take the chill out of your current energy bill.